It must be assumed that all power lines are energized unless the utility owner/operator confirms that the power line has been and continues to be de-energized and it is visibly grounded at the worksite. To avoid contact to power lines when operating cranes the employer must follow the regulations of 1926 Subpart CC. Follow these three steps every time a crane is operated.

Step #1

A hazard assessment of the worksite must be performed to identify the work zone. As the unwritten rule of OSHA states “If it is not documented, it did not happen”.

When identifying the work zone OSHA gives employers two options. The first option is to mark the work zone boundaries with flags (or range limiter / warning devices) and prohibit the operator from operating the equipment past the marked work zone boundaries. The other option would be to define the work zone as the entire 360 degree maximum working radius of the equipment.

Step #2

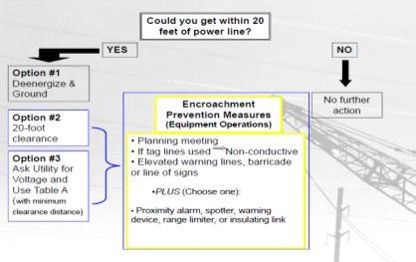

After determining the work zone, it must be determined if any part of the equipment, load line or load (including rigging and lifting accessories) could, at the equipment’s maximum working radius, get closer than 20 feet to a power line within the determined work zone. If not, then no further safety precautions need to be taken to avoid power lines (that is if the equipment stays within the determined work zone). If the equipment could get within 20 feet of power lines, then further requirements must be met.

Step #3

One of the following three OSHA requirements must be met if the equipment could get within 20 feet of power lines inside the determined work zone at the equipment’s maximum working radius.

Option #1

Request that the power line be de-energized and grounded by the utility owner/operator. If this option is chosen you must confirm that the line is de-energized and grounded prior to proceeding with operations. Requesting written documentation from the utility owner/operator would be a great way to confirm this information.

It is important to note that OSHA does not require utility companies to de-energize power lines. If the utility owner/operator does refuses to de-energize the power line then another employee protection option must be selected.

Option #2

Ensure that no part of the equipment, load line, or load (including rigging and lifting accessories), can get closer than 20 feet to the power line by implementing ALL of the following measures:

- Conduct a planning meeting with the operator and the other workers who will be in the area of the equipment or load to review the location of the power line(s), and the steps that will be implemented to prevent encroachment/electrocution.

- Use clean and dry non-conductive tag lines.

- Erect and maintain an elevated warning line, barricade, or line of signs, in view of the operator, equipped with flags or similar high-visibility markings, at 20 feet from the power line.

- If the operator is unable to see the elevated warning line, a dedicated spotter*, who is in continuous contact with the operator, must be used.

- Implement at least one of the following measures:

- A proximity alarm set to give the operator sufficient warning to prevent encroachment.

- A dedicated spotter* who is in continuous contact with the operator. (Not allowed as one of the options if already required due to the operator unable to see the elevated warning line.)

- A device that automatically warns the operator when to stop movement, such as a range control warning device. Such a device must be set to give the operator sufficient warning to prevent encroachment.

- A device that automatically limits range of movement, set to prevent encroachment.

- An insulating link/device, (listed, labeled, or accepted by a Nationally Recognized Testing Laboratory in accordance with 29 CFR 1910.7), installed at a point between the end of the load line (or below) and the load.

*The dedicated spotter must:

- Be equipped with a visual aid to assist in identifying the minimum clearance distance.

- Examples of a visual aid include, but are not limited to: A clearly visible line painted on the ground; a clearly visible line of stanchions; a set of clearly visible line-of-sight landmarks (such as a fence post behind the dedicated spotter and a building corner ahead of the dedicated spotter)

- Be positioned to effectively gauge the clearance distance.

- Where necessary, use equipment that enables the dedicated spotter to communicate directly with the operator.

- Give timely information to the operator so that the required clearance distance can be maintained.

Option #3

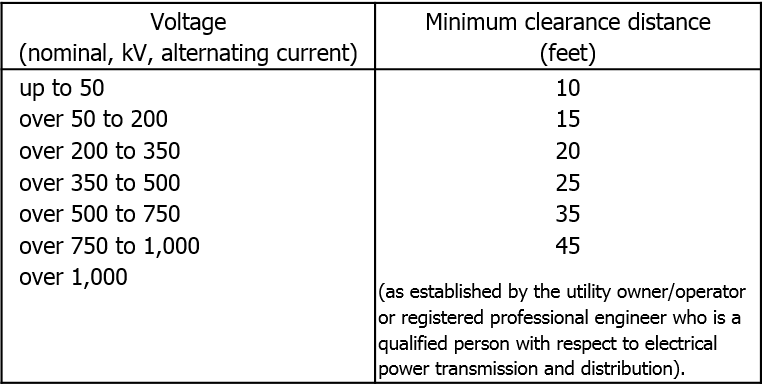

Request the line’s voltage from the utility owner/operator and utilize Table A – Minimum Clearance Distances to determine if any part of the equipment, load line or load (including rigging and lifting accessories) could, at the equipment’s maximum working radius, get closer than the specified minimum clearance distance (in feet) to a power line within the determined work zone. If not, then no further safety precautions need to be taken to avoid power lines (that is if the equipment stays within the determined work zone). If the equipment could get within the specified minimum clearance distance set forth in Table A, then the requirements specified in Option #2 must be met (replacing the 20 foot clearance distance with the specified minimum clearance distance set forth in Table A).

It is important to note that the utility owner/operator is required to provide the line’s voltage two working days (include all calendar days except weekends and holidays) after receiving a proper request for this information. For example, if an electric utility receives a request for voltage information on one of its distribution lines on a Friday, it will have until the end of the business day on the following Tuesday to provide the necessary information (assuming there are no holidays in between).

NOTE: The value that follows “to” is up to and includes that value. For example, over 50 to 200 means up to and including 200kV.

If the proper minimum clearance distances can NOT be breached by any part of the equipment, load line or load (including rigging and lifting accessories) could, at the equipment’s maximum working radius, get closer than the specified minimum clearance distance (in feet) to a power line within the determined work zone.

350 kV and Above

Follow the same three steps, replacing the 20 foot minimum clearance distance with 50 feet.

For power lines over 1,000 kV, the minimum clearance distance must be established by the utility owner/operator or registered professional engineer who is a qualified person with respect to electrical power transmission and distribution.